MGP 1

![]()

Plant for spraying and pouring of bicomponent adhesives and foams

The MGP1 plant is designed with a modular criterion combining the storage, dosing and automation for the product supply. The plant layout is studied to meet the specific customer’s requirements considering the field of use and the type of raw materials used. MGP1 permits the supply of: adhesives, rigid and flexible foams, rigid or elastomeric compact products. On the basis of the model, the equipment doses, mixes and supplies to high or low pressure the material, using self-cleaning mixing heads or washing type. Magmamacchine directly trains the equipment staff for the use and maintenance transferring the necessary know-how.

AMG MIXING HEAD

The AMG is the standard mixing head [1] assembled on the plant; it is of the air self-cleaning type, with the possibility to use liquids for the washing of the mixing chamber.Using special adapters, it is possible to supply the products by spraying and by casting, using, in this case, a dismountable multi-holes sprinkler [2]. The mixing head opening/closing system is of pneumatic type automatically controlled by prefixed sequences. The mixing chamber and its relevant block with seals are easy replaceable since they are fixed to the head body by a bayonet system; this permits the maintenance reducing at minimum the machine stops during working.

MOVEMENT AND PUMPING

The volumetric pumps [3] are at high pressure with the possibility to change the mixing ratio. The pump movement is of hydraulic type in order to reach very high pressures. For some works, it uses the gear dosing system treated by special inside hardening process for special products.

AUTOMATION AND SAFETY SYSTEMS

The control panel contains all the devices necessary to stop the running of the machine in case of anomalies and protect the machine and the operator. By means of the touch-screen operator’s panel [4], it is possible to manage the plant working and control parameters. It prepares some software for the customer’s application with variable production receipts and specifications: speed, resin delivery, machine cycle times. The AMG supply head is moved by linear tracks [5] with reciprocation speed up to 2 m/sec.

STORAGE AND THERMOREGULATION

The department tanks [6] keep the running temperature by a heating system (cooling on demand) and stir. The machine component heating is made by heat exchanger in line and an electric system at low tension is used for the piping. On the electrical panel are installed all the devices to manage the temperatures of each component.

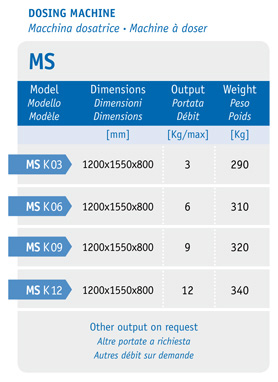

TECHNICAL INFORMATIONS

VIDEO

DISCONTINUOUS PANELS SPRAY GLUE

MGP1 PLANT FOR “ORMA MACCHINE”

GLUEING ISOTHERMAL PANELS FOR VAN