MS

![]()

High pressure machine for bicomponent resins (variable ratio)

The machine MS is the result of years of direct experience in the field of spraying, pouring and injection of bicomponent materials. The equipment doses, mixes and dispenses at high pressure, using as standard, self-cleaning mixing heads. The field of work changes from rigid and flexible expanded foams, to the adhesives, to the several filled products and to the coating with elastomers, polyurea and RIM. The reduced dimensions and high reliability allow a high quality standard of work and a special handling. Magmamacchine trains directly the operators in charge to the plant about usage and maintenance, providing also the necessary know-how.

MIXING HEAD HMG

The mixing head HMG [1] is self-cleaning by air, with the possibility to use, if needed, flows of other nature to wash the mixing chamber. Thanks to special adaptor fittings, it is possible to dispense the products by injection, pouring and spraying. The operating system (opening/closing of the mixing head) of the HMG is pneumatic and it is manually controlled by the operator.The mixing chamber and its block with the seals are easy to replace because connected to the head body by a bayonet system, which makes easier the maintenance reducing the machine stops during working.

MOVEMENT AND PUMPING

The volumetric pumps [2] are at high pressure with the possibility to change the mixing ratio and to check it easily and directly. The pumps movement can be hydraulic or pneumatic, according to the customer’s needs, the mechanical systems are oversized so to reach working pressures of 150 bar.

THERMOSTATIZATION

The high pressure hoses can have a length of more than 100 mt with different diameters depending on the outputs. The components heating on the machine is operated by in line heat exchangers [3]; for the hoses a low voltage electric system is used. On the control panel are placed all the devices for the temperature control of each component.

SAFETY

All the components are of a high quality level to avoid breakages or damages. The control panel mounts all the devices to stop working in case of anomaly so to protect the machine and the operator. The MS is fitted with all the devices to work in safety both for the electric parts and for the mechanical ones with fixed protection as carters etc., of safety pressure gauges with divider [4] and 3 degrees of components filtering for the best reliability.

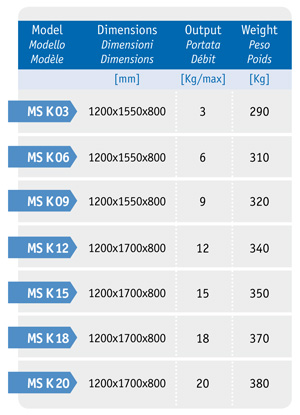

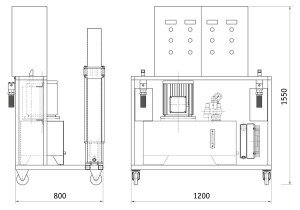

TECHNICAL INFORMATIONS

VIDEO

SPRAY PUR

MAINTENANCE HMG SPRAY GUN

METAL SHEET INSULATION FOAM

REINFORCEMENT SHOWER TRAY WITH ECOMAG

REINFORCEMENT BATHTUBS

SPRAY PUR

VERTICAL SURFACE INSULATION

POLYUREA COATING BAYER

REINFORCEMENT SHOWER TRAY WITH ECOMAG

POLYUREA COATING FORNITURE